Fiber cement board is divided into inner fibers

At present, most of the domestic use of asbestos fiber to enhance the role of this kind of fiber cement board is called chrysotile fiber cement plate; the other kind is non-asbestos fiber, with pulp, wood chips, glass fiber to replace asbestos fiber to enhance the role of the general term asbestos-free fiber cement plate. (Explosion-proof board)

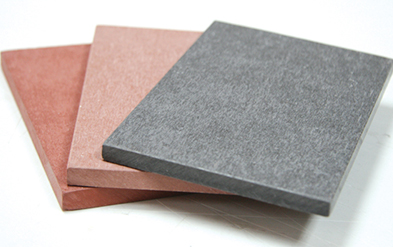

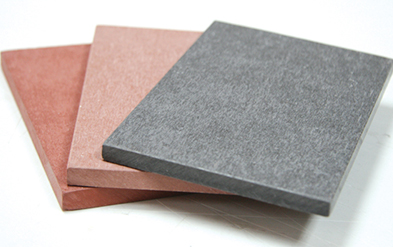

Fiber reinforced cement boards are classified according to density

Low density is 0.9-1.2g/cm3, medium density is 1.2-1.5g/cm3, high density is 1.5-2.0g/cm3. Low density is generally used in low-grade building ceiling partition wall and other parts, medium density is generally used in middle-grade building partition wall ceiling, high density is generally used in high-grade building steel structure exterior wall, steel structure floor slab, etc. At present, China's fiber reinforced cement slab according to the national construction line. Industry standards fall into two categories. High density fiberboard is easy to deform because of its shortcomings, and the deformability coefficient of medium and low density products is a little smaller.

Compression force of fibre reinforced cement board

There are pressure plate and pressure plate. Medium and low density fibre reinforced cement boards are all non-compressive boards, while high density fibre reinforced cement boards are pressure boards. Pressure plate, also known as fibre cement pressure plate, needs special press production, which can not be done by enterprises without press. According to the density, the fibre cement pressure board can be divided into: 1) ordinary board, density 1.5-1.75g/cm3; 2) superior board, density 1.75-1.95g/cm3; 3) superior board, density 1.95g/cm3 or more.

According to thickness, it can be divided into 1) ultra-thin plate, 2.5-3.5 mm; 2) conventional plate, 4-12 mm; 3) thick plate, 13-30 mm; 4) ultra-thick plate, 31-100 mm. General manufacturers can not make ultra-thin and ultra-thick plates, which is also an important basis for measuring the production capacity and technical level of enterprises in the industry.

Fiber cement board is a kind of board made of cement as basic material and adhesives, mineral fiber cement and other fibers as reinforcing materials, through pulping, shaping, maintenance and other processes. Fiber cement board is used in various domestic power plants, chemical enterprises and other electricity-intensive places for fire prevention and flame retardant. It is also the best fire-retardant material for interior decoration fire-retardant projects in large shopping malls, hotels, hotels, document halls, closed garment markets, light industry markets, cinemas and other public places.

Fiber cement board abbreviated as FC board

Fiber reinforced cement board, also known as fiber reinforced cement board, is a construction cement plate made of fibers and cement as the main raw materials. It is widely used in various fields of construction industry with its superior performance. According to the different adding fibers, it can be divided into chrysotile fibre cement board and asbestos-free fibre cement board. According to the different forming pressure, it can be divided into fibre cement pressure board and fibre cement pressure board.

Specifications

General specification: length: 2000mm-2440mm

Width: 1000mm-1220mm

Common thickness: 4-12 mm

The thickness can be extended to 2.5mm-90mm in China. The sizes of domestic boards are generally 1200 x 2400 or 1220 x 2440. The former is the domestic general standard and the latter is the international general standard. (Other smaller sizes can be cut at will)

According to density, it can be divided into three categories: high, medium and low. The edge of low density plate is rough after cutting, and that of high density plate is neat after cutting.

Fiber reinforced cement boards with different physical properties such as specifications and densities have different heat and sound insulation properties. Generally speaking, the higher the density, the thicker the thickness of the board, the better the heat and sound insulation performance. In addition, its insulation performance is worthy of recommendation, such as application in distribution room.

Plate movement and cutting

The fiberboard itself is heavier, so it needs at least two people to move the whole uncut board. The thickness of 4mm-6mm belongs to the thinner plate. The thin plate is fragile relative to the thick plate. It needs to be moved carefully before installation. If it is not protected carefully, it is fragile and damaged easily.

Installation of fiberboard requires at least two people, one person to stabilize the position of the board, and one person to fix it with special nails.

Cutting fibre reinforced cement boards usually requires an electric saw or a mechanical tool. There are three ways to cut fibre reinforced cement boards:

1. Sheet can be broken by heavy cutting tools.

2. Use Fiber Cutting Machine (Australian Cutting Method)

3. Heavy or high-density plates require electric sawing

In the cutting process, we must pay attention to the wind direction, try to avoid powder inhalation in the body, wear masks or special protective tools, plate powder into the lungs for a long time may lead to disease.

After installation, various coatings can be applied for finishing (waterproof coatings are needed where exposed to air). Fixed joints need to be filled with wood blocks or strips, and the whole surface of the board needs to be painted, so as to prolong the service life of the board. Installation of fixed and painted fiberboard, its maintenance workload is very small. Thick and high-density plates have good impact resistance, but thin and low-density plates need to be protected from external impact. Compared with wood wallboard, fiber cement board has good waterproof, fire-proof and sound-proof effect, and it does not produce termites, is not easy to rot, and has better corrosion resistance.